Beyond Compliance: A Strategic Tool for Operational Technology

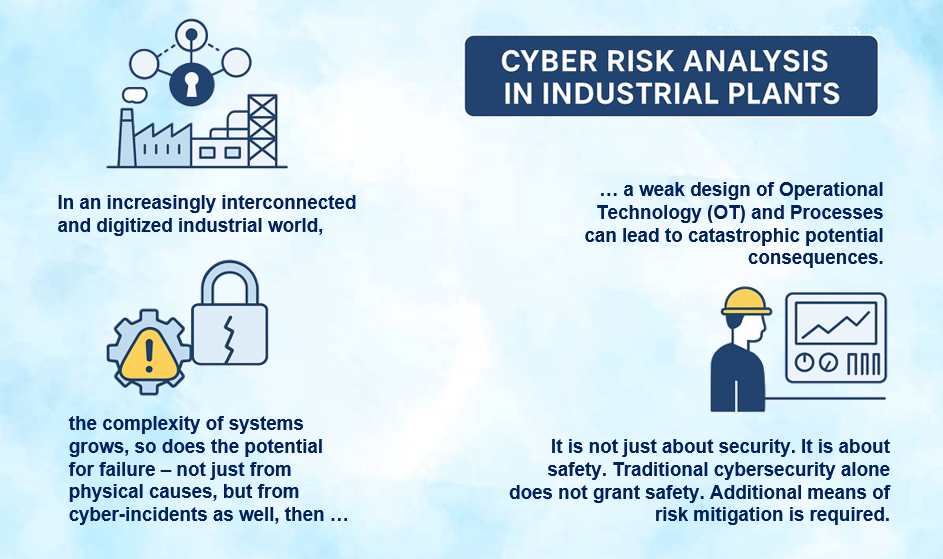

In an increasingly interconnected industrial world, Operational Technology (OT) has become the backbone of modern production. Yet, as the complexity of systems grows, so does the potential for failure—not just from physical causes, but from cyber-incidents as well.

Risk analysis, when viewed strategically, is no longer just about compliance. It’s a critical enabler of resilience, informed decision-making, and long-term operational sustainability.

Risk Analysis: From Obligation to Operational Compass

Risk assessments are often seen as mandatory exercises—conducted to satisfy regulators, check boxes, and pass audits. While compliance is important, this mindset limits the value of risk analysis.

When approached strategically, risk analysis serves as a compass rather than a constraint. It guides organizations through uncertainty, prioritizes what matters most, and helps align technical realities with business goals.

The Dual Nature of Risk: Physical Meets Digital

In industrial environments, risks come from both the physical and digital realms. Traditional failure modes—equipment breakdowns, human errors, and environmental hazards—remain relevant. But they now coexist with cyber risks: malicious actions, unauthorized access to control systems, configuration errors, and cascading effects from IT/OT convergence.

A compromised PLC or a misconfigured firewall can disrupt not only one machine, but an entire production line—or worse, introducing safety hazards and dangers.

A true risk perspective must consider the full ecosystem, from the sensor on the plant floor. The consequence-centric methodology should be used to prevent potential consequences from happening, instead of a mere cyber-incident-centric. Cyber-Incident alone without potential consequences does not pose a risk to the plant.

Shared Ownership: Risk is Not Just for Safety or Security

Too often, risk analysis is siloed within safety, cybersecurity, or engineering departments. But in reality, risk touches every corner of the operation.

- Operations know where the production bottlenecks are.

- Maintenance understands the history of equipment failures.

- IT and OT teams grasp the digital infrastructure and its vulnerabilities.

When all stakeholders contribute to risk analysis, the result is more accurate, holistic, and actionable.

Prioritization is Strategic, Not Absolute

Not every vulnerability needs to be eliminated—nor can it be. The focus should be on evaluating risks based on operational impact, not just probability.

Consider this:

If this controller goes offline, what processes will be affected? What’s the potential downtime? What’s the risk to safety?

This approach connects technical risks to business operational outcomes, enabling better prioritization and investment in mitigation.

Conclusion: Risk as a Lever for Resilience

Risk analysis in industrial plants is far more than a compliance obligation. It is a dynamic tool for navigating complexity, enabling cross-functional collaboration, and strengthening operational agility.

Organizations that integrate risk thinking into their OT strategy are better prepared—not just to avoid failures, but to adapt, respond, and grow.

Let’s Open the Discussion

How is your organization approaching risk today?

Is it still an annual audit item—or is it evolving into a strategic function embedded in daily decision-making?

I’d love to hear your perspective. Feel free to comment or share your experiences.