To address this issue, we must start from a common definition between what digital transformation, digital systems and digitalization mean. Digitization consists of recording data in digital form, digital systems solve a need using technology, while digital transformation has a broader concept. When we talk about digital transformation, we refer to the process of adapting or reviewing current business processes to incorporate digital strategies and technology into the company.

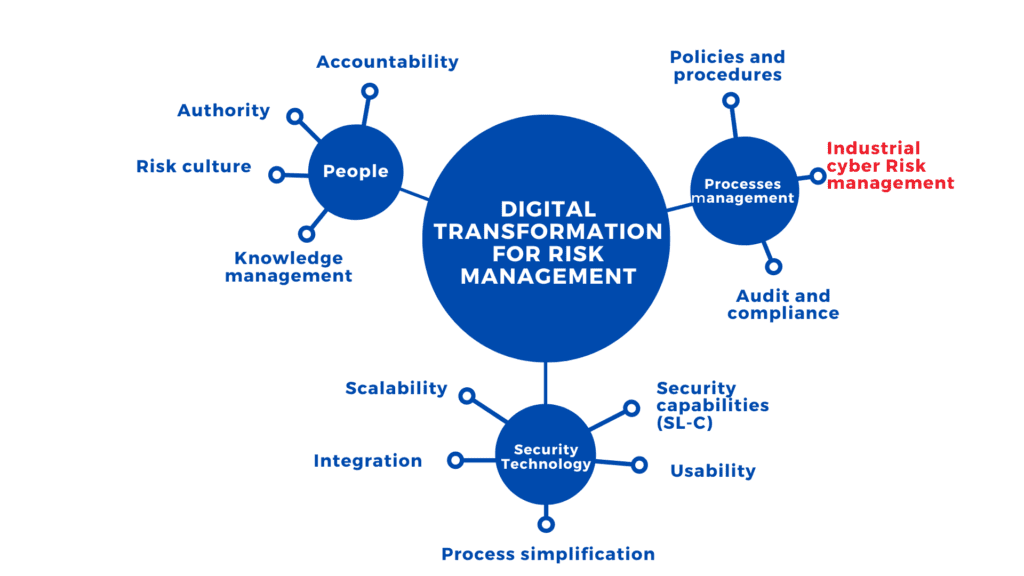

In our case, in industrial cybersecurity it consists of achieving the integration and transformation of security technologies, management processes and people to improve, simplify and add value to the organization, fulfilling the main objective of industrial cybersecurity, which is to protect risk recipients.

This obtains maximum benefit from the use of technology, reducing bureaucracy to the minimum through digital automation, eliminating the need for the company to see the need to develop countless procedures and records. Automating time-consuming tasks, by applying knowledge, for example, can allow employees to focus their attention on more skilled tasks that will generate revenue or reduce business operating costs. Task automation will also help boost morale, as staff members won’t be bogged down by repetitive tasks or low-value jobs, such as searching endless amounts of information, documents, and records.

Isolated systems of complex integration and adequacy – Digitization: Inefficient and Expensive

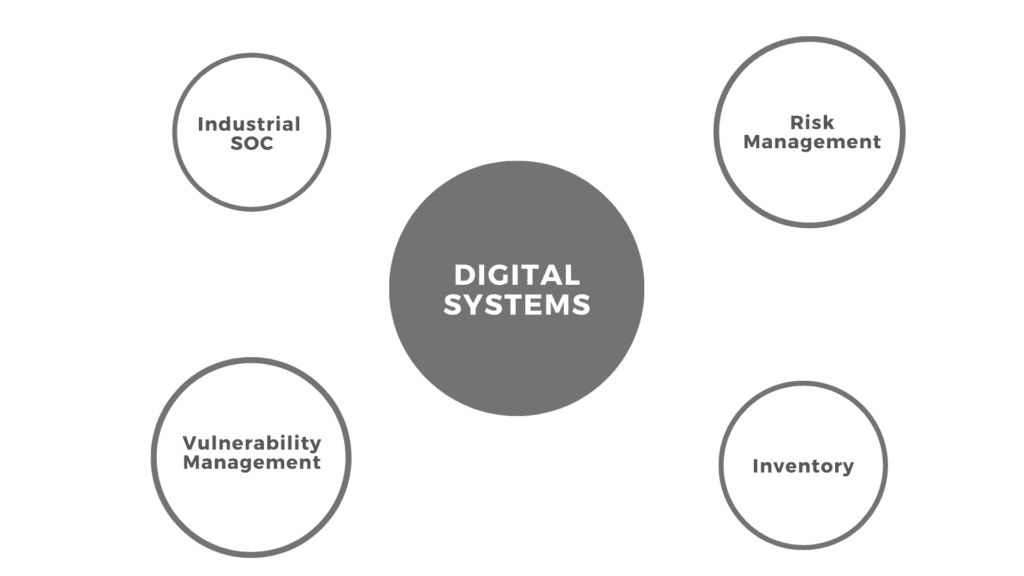

The installation of multiple digital systems does not guarantee interoperability between them, being that usually each one develops with its own data models, proprietary issues and weaknesses. Especially those weaknesses that have to do with the interpretation and compliance with the rules. Each with a particular vision of the problem, making collaboration a headache, against the benefits of true digital transformation, often duplicating unnecessary work.

The digital transformation in the industry represents a retro towards organizations, because according to statistics only 30% of projects are successful, and its main failure is to ignore the identification of the elements and their integration into a digital transformation ecosystem, focusing their strategy on digitalization or isolated technological solutions.

Most of the time, different systems emerge as initiatives with different visions of how to solve the problem of industrial cybersecurity, competing instead of collaborating. This is even worse when choosing the wrong vendors, technologies, and solutions, without a true in-depth knowledge of the solution.

We frequently observe how many organizations are spending extremely high budgets on solutions that do not work, and that lack the pillars of industrial cybersecurity, due to lack of knowledge and experience. They will only fail and realize it after wasting all the resources they had available.

Orchestrated systems in a single natural solution without cost overruns – Digital Transformation: Efficient and Effective.

In this era of digital transformation, technologies cannot become a pain for organizations, they must be the answer that adds value. That is why it is so important to identify and know the ecosystem in which the transformation strategy is going to be developed, that makes the difference with respect to digitalization.

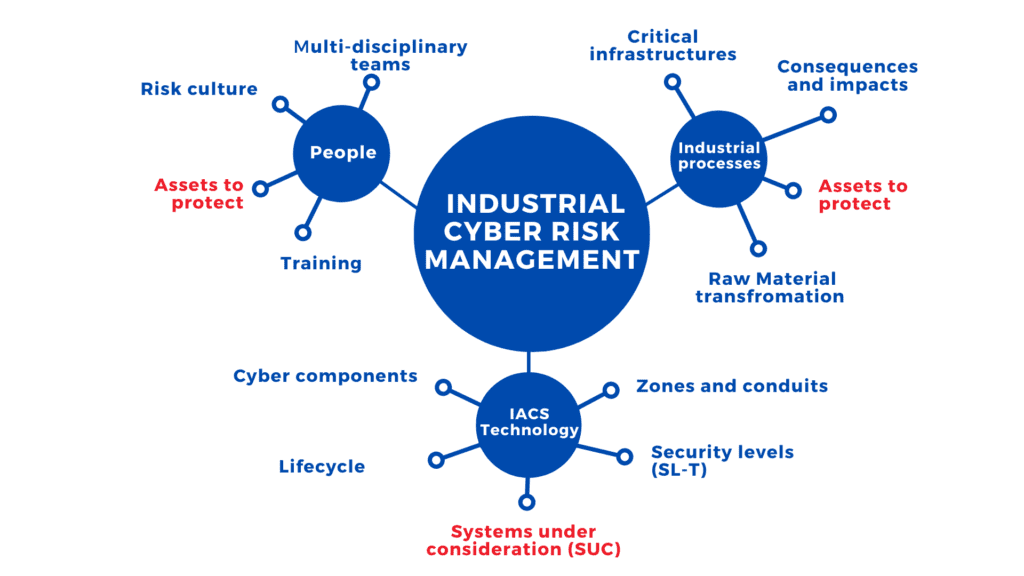

First, we must understand the requirements and needs to achieve true digital transformation in the realm of industrial cyber risk management. Identify the key factors that will make people, processes, and technology work as one naturally and automatically, in a consistent and error-free way.

For an organization to incorporate cybersecurity, it is necessary to go through a process of cultural change in the organization. Many organizations fail in industrial cybersecurity because they see it as a project with a beginning and an end in a place of a cultural change in the organization, never to end. People play a fundamental role in this process of change.

Effective, efficient, and fast government over industrial cyber risk management is required. Companies can no longer take years and years to reach their goals, let alone make mistakes. The speed with which events unfold in the security space does not give respite, and they do not forgive. Those who fail to make the change in a timely manner will have failed.

The incorporation of technology as tools that will mitigate risks and manage governance efficiently and optimally are a crucial piece. These must automatically resolve as much as possible, without losing sight of the fact that the objectives are in the real and effective mitigation of cyber risk to protect the assets of the organization that really matter. That is, and in part, to comply with the appropriate standards.

From our experience in WisePlant we have developed an ecosystem that integrates the elements, guarantees the simplification and improvement of processes, reduces costs and time. All this is achieved thanks to a program developed and centralized in the management of industrial cyber risk.

The ZCM system was developed from a blank paper, without pre-established models, only with a list of requirements and objectives that allow complete, efficient, and effective industrial cyber risk management. A system that allows integral management complying with all the requirements of international standards, with a common data model, and allowing interoperability with other systems of the organization.

We have designed and developed the ZCM system to develop an industrial cybersecurity program with the following results:

- Agile management processes that translate into reduced effort in the execution of the industrial cybersecurity life cycle.

- Less time in evaluation and implementation.

- Less implementation costs, only countermeasures are placed where they are required and guaranteeing assurance.

- Efficient monitoring, without false positives and without high costs.

- Industrial risk culture and integration of multidisciplinary teams, all cooperating towards long-term assurance.

- Technologies that enable data integration, scalability and analysis. All-in-one centralized in an industrial cyber risk management system.

- Synchronous and asynchronous system, we do not depend on the availability of people to advance in the industrial cybersecurity program. Each person works according to their schedules.

If you want to understand and understand how we achieve digital transformation in industrial cybersecurity, write to us and we will chat.

We cannot conclude that digitalization itself is wrong or wrong, but we can say that the possibility of introducing significant changes is being lost that in addition to solving a specific issue will contribute to an integral organizational improvement.

Implementation of technological solutions – Digitalization

- Complex management processes

- It depends a lot on people

- Depends on many platforms

- Difficult to maintain over time

- Isolated technological solutions

Comprehensive Organizational Change Management – Digital Transformation

- Agile management processes

- Very low administrative burden

- Knowledge is transferred

- The entire management process in one

- Comprehensive and scalable technological solutions

Get Involved & Participate!

Comments